A NEW ANSWER FOR VIRGIN QUALITY

CIRCULAR PLASTIC PRODUCTION.

CIRCULAR PLASTIC PRODUCTION.

1

CIRCULAR

OLEFINS DEMAND

OLEFINS DEMAND

- Polyolefins represents 45 % of global plastic production.

- Olefins are the first chemicals produced globally with 480 Mt/year.

- Total global olefins production performed in only 220 petrochemicals assets.

the circular

olefins

challenge

olefins

challenge

2

EU PPWR REGULATION

- Regulation targets: only accessible by chemical recycling technologies

- 25% recycled content in Food Grade and Contact Sensitive packaging by 2040.

- Chemical recycling capacity needed: 10 Mt/year.

WE PROPOSE A

LOW CARBON

SOLUTION FOR

NON VALORISABLE

PLASTIC WASTES.

LOW CARBON

SOLUTION FOR

NON VALORISABLE

PLASTIC WASTES.

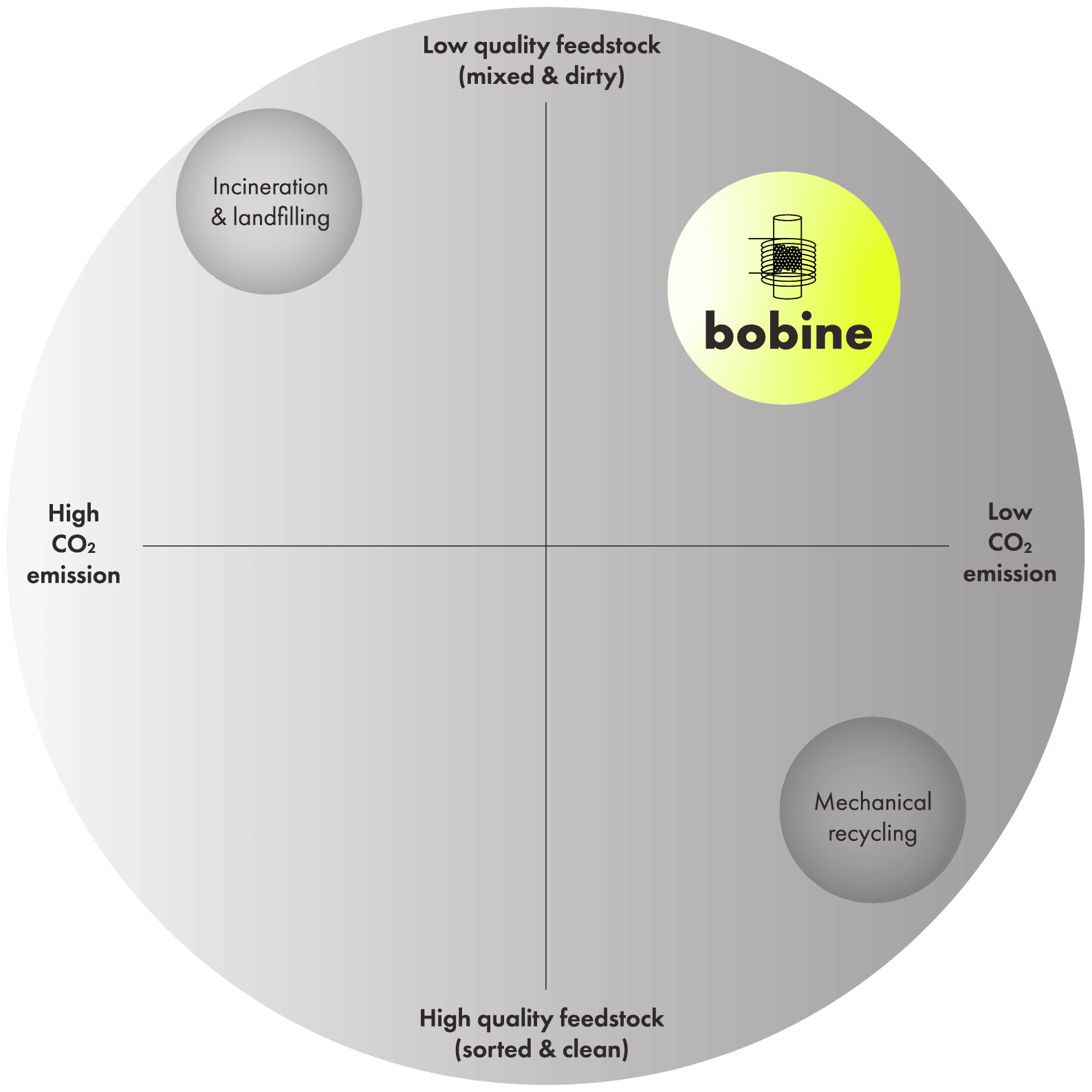

- Clean and separated rigid PO wastes compatible with mechanical recycling.

- Other PO wastes considered as « Hard To Recycle » are incinerated or landfilled.

- bobine brings a new recycling offer on the market, complementary to the mechanical recycling.

Existing solutions VS feedstock

& environmental impact

& environmental impact

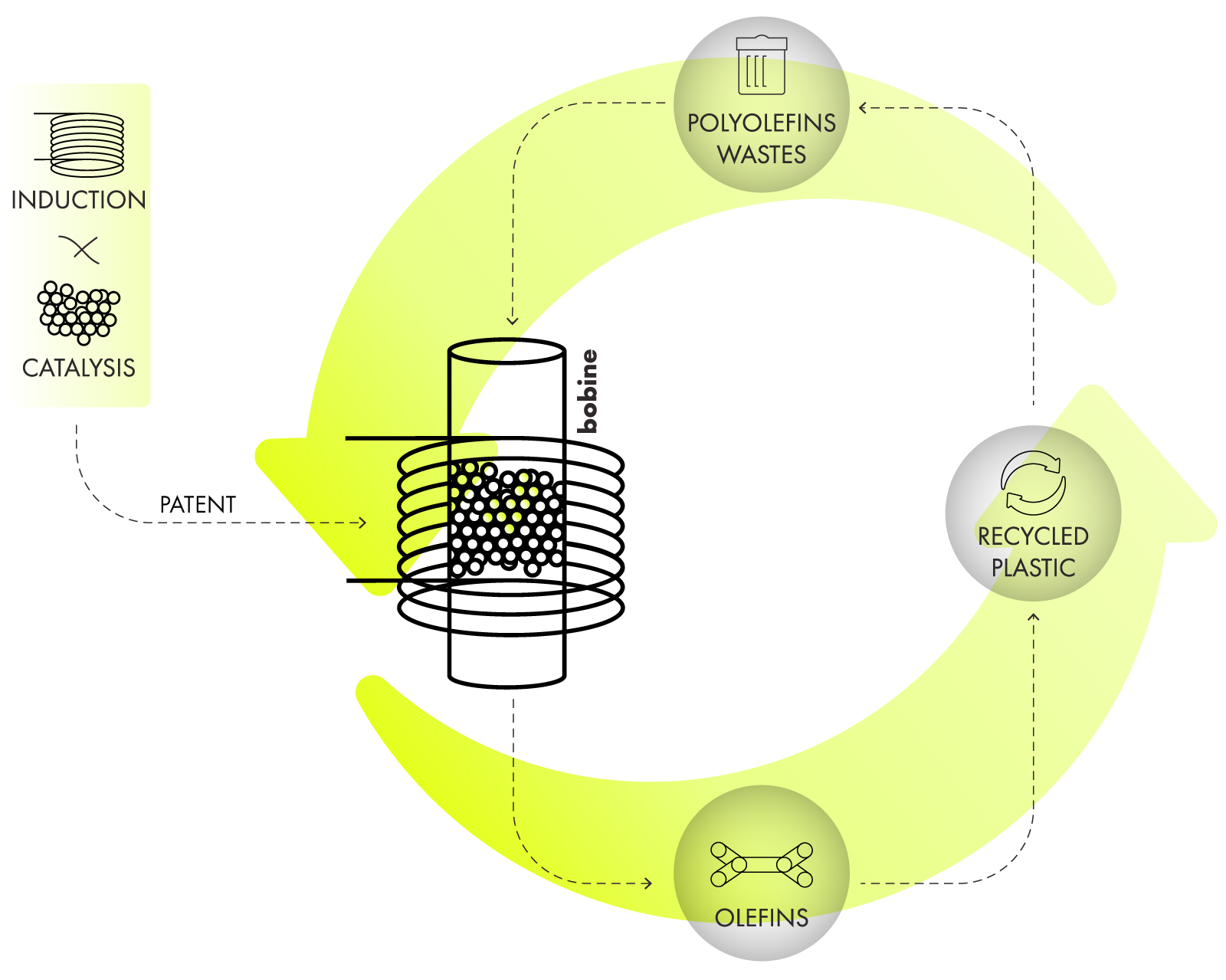

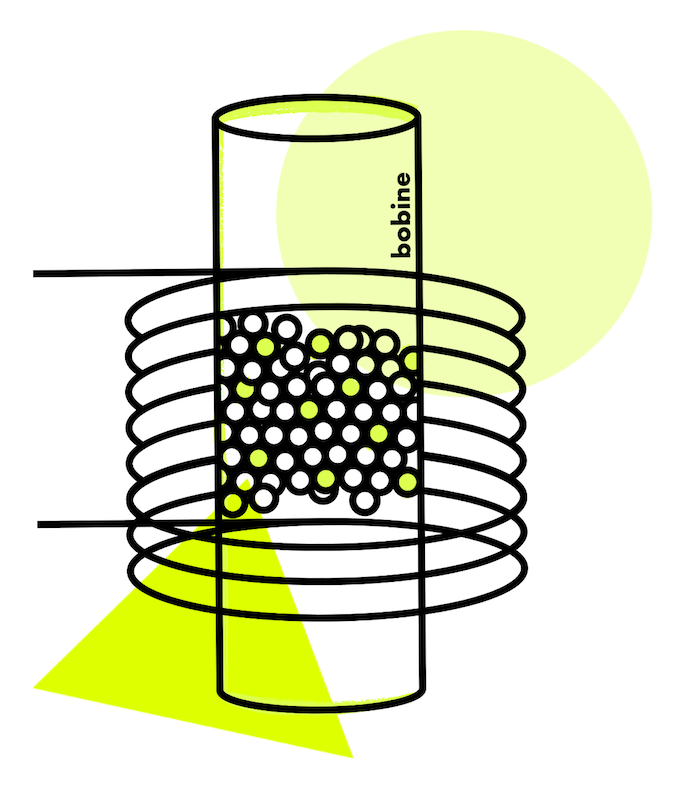

Our induction activated catalysis technology

A WORLD

FIRST

CHEMICAL

CONVERSION

METHOD.

FIRST

CHEMICAL

CONVERSION

METHOD.

TECHNOLOGICAL BRICK

IP PROTECTION

- World First Combination of two mature and robust technologies.

IP PROTECTION

- 1 princept patent applied in july 2022.

Exclusive Licence granted by SATT Conectus Alsace. - 2 additional patents.

FROM END PLASTIC WASTES

TO VIRGIN QUALITY POLYMERS.

TO VIRGIN QUALITY POLYMERS.

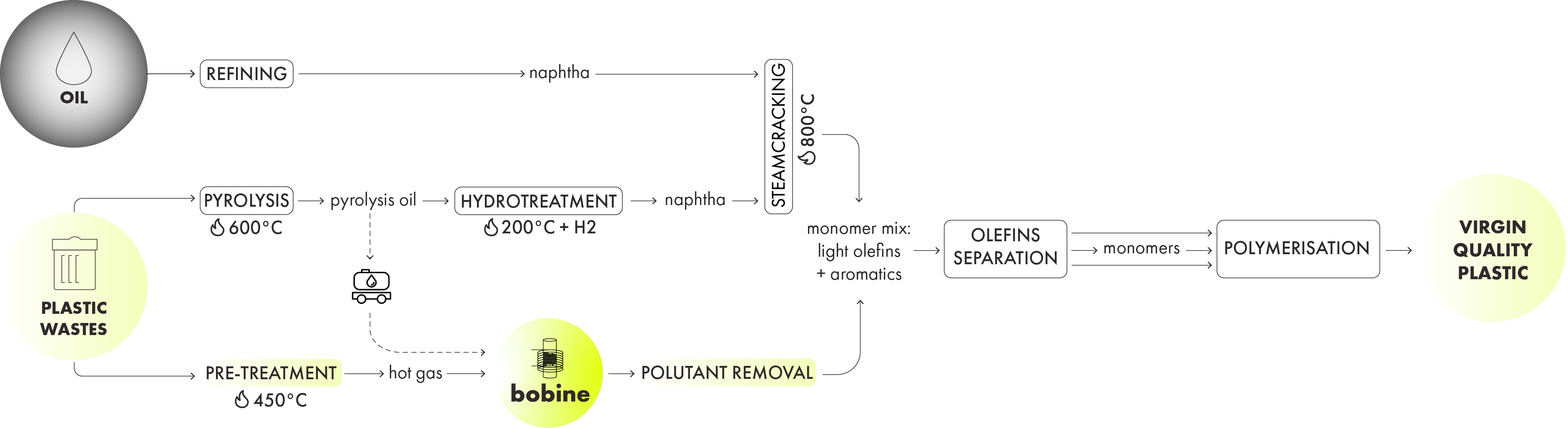

process & application

AN OUTSTANDING HIGH PERFORMANCE

CHEMICAL RECYCLING VALUE CHAIN

CHEMICAL RECYCLING VALUE CHAIN

Gains compared to pyrolysis

* steamcracking

- +45% conversion rate

- -60% energy demand

- -45% production cost

- -55% CO2 emission

-

NO

STEAMCRACKING

FURNACE -

FULL

TRACEABILITY - 100% ELECTRIC

-

NO

HYDROTREATMENT - FOOD GRADE

-

CONTACT

SENSITIVE

TECHNOLOGY SCALE

UP ROAD MAP.

UP ROAD MAP.

demo v1.

Lab Bench

400 g/day

Validated at lab

Validated at lab

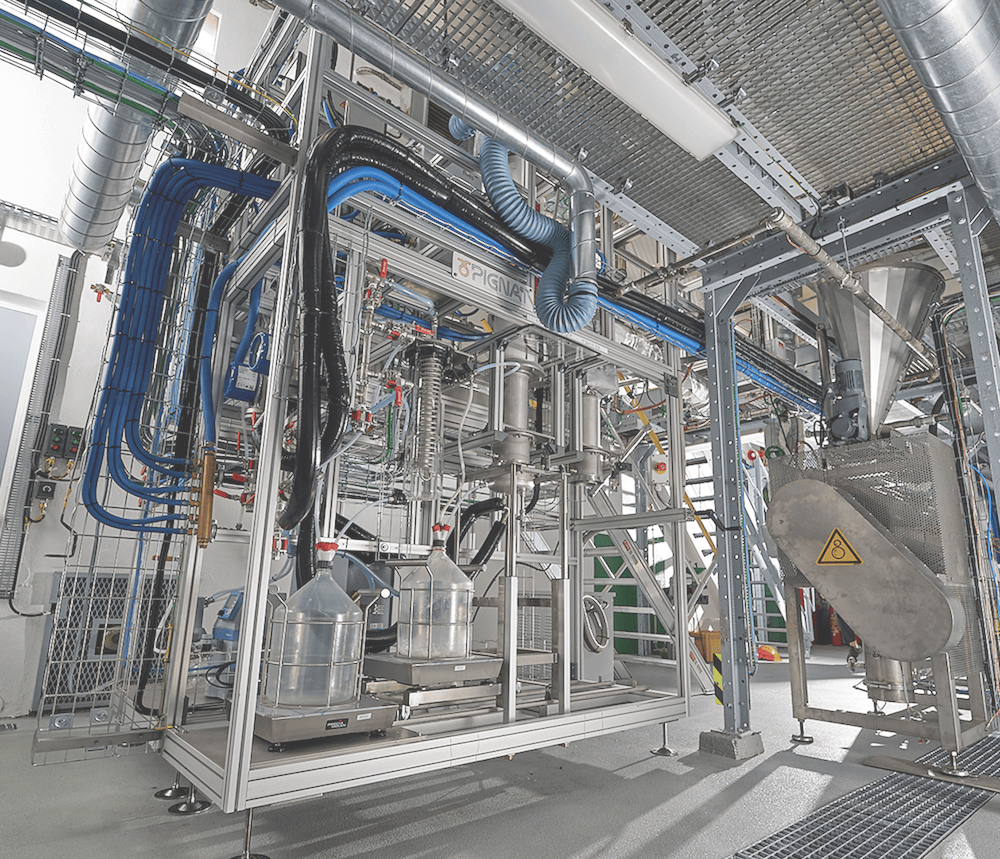

demo v2.

Continuous Pilot Unit

100 kg/day

Co-operated with Michelin

100 kg/day

Co-operated with Michelin

demo v3.

Pre-Industrial Demonstrator

1 ton/day

Under engineering - co-operated with Michelin

Operational by 2026

1 ton/day

Under engineering - co-operated with Michelin

Operational by 2026

first unit.

Industrial Demonstrator

30 tons/day

Final target

Operational by 2028

30 tons/day

Final target

Operational by 2028

v2 continuous

pilot unit last

updates.

pilot unit last

updates.

→ A daily start & stop running with volontary shut down & spontaneous start-up.

→ A pilot unit robust for at least 12 hours.

→ A large quantity of olefins, stable and

continuous, measured every 15 minutes.

→ Next step: a 24h test run with mixed plastics scheduled Q2.

They are involved with us:

THE EXECUTIVE TEAM

Fabien GUILLEMAUT

Head of Piloting

Head of Piloting

_ 25 years on polymer

production piloting

production piloting

Pauline PACQUET

R&D Engineer

R&D Engineer

_ PhD in Polymer Chemistry

_ 5 years experience in petrochemical industry

_ 5 years experience in petrochemical industry

strategic advisors, experts, scientifc committee & industrial committee

Board of advisors

Statutory Quaterly Meeting

Governance

Finances Strategy

Governance

Finances Strategy

Jean-Bernard LARTIGUE

President

Ex President of TOTAL

Petrochemicals

Yannick LAFUE

CEO BLACKLEAF

Stéphane WAMBERGUE

CEO & President of SICAT & ACM

Jean-Claude PLUMAIL

Ex Commercial Director Process & Licencing at AXENS

Julien LAURENT

Banker

Laurent BLAISONNEAU

Ex CEO of ENEA Consulting.

Certified Administrator

President

Ex President of TOTAL

Petrochemicals

Yannick LAFUE

CEO BLACKLEAF

Stéphane WAMBERGUE

CEO & President of SICAT & ACM

Jean-Claude PLUMAIL

Ex Commercial Director Process & Licencing at AXENS

Julien LAURENT

Banker

Laurent BLAISONNEAU

Ex CEO of ENEA Consulting.

Certified Administrator

Industrial committee

Statutory Quaterly Meeting

Scale-up Road Map Strategy

Scale-up Road Map Strategy

Grégoire SARRAIL

CTO Mecaware

Stephane WAMBERGUE

CEO SICAT

Jean-Claude PLUMAIL

Ex Commercial Process & Licensing Axens Director

Alain ALBERT

Project Director NALDEO Technologies

CTO Mecaware

Stephane WAMBERGUE

CEO SICAT

Jean-Claude PLUMAIL

Ex Commercial Process & Licensing Axens Director

Alain ALBERT

Project Director NALDEO Technologies

Scientific committee

Statutory Quaterly Meeting

Reasearch Developement

perspectives

Reasearch Developement

perspectives

Charlotte PHAM

Inventor - CTO SICAT

Cuong PHAM-HUU

Inventor - CNRS Director

Cuong DONG VIET

Inventor – 5 years R&D on bobine

Laï TRUONG PHOC

Inventor – 5 years R&D on bobine

Jean-Mario HNUT

Inventor – 5 years R&D on bobine

Anthony DUFOUR

CNRS Research director

Inventor - CTO SICAT

Cuong PHAM-HUU

Inventor - CNRS Director

Cuong DONG VIET

Inventor – 5 years R&D on bobine

Laï TRUONG PHOC

Inventor – 5 years R&D on bobine

Jean-Mario HNUT

Inventor – 5 years R&D on bobine

Anthony DUFOUR

CNRS Research director

Strategic consultants

Call-Off basis

Olivier LEPEZ

Pyrolyzer technology expert

Ex ETIA founder and CEO

Michael DUMONT

Induction expert

Juliette JANNES

Steamcracker expert

Ex ExxonMobil

Pyrolyzer technology expert

Ex ETIA founder and CEO

Michael DUMONT

Induction expert

Juliette JANNES

Steamcracker expert

Ex ExxonMobil

WANT TO KNOW MORE

ABOUT OUR TECHNOLOGY?

ABOUT OUR TECHNOLOGY?

Branding & web design: studio Gé. – Development & integration: Akalmie.fr